Concrete Reinvented

Revolutionary graphene-infused concrete technology for infrastructure that lasts centuries, not decades.

Why Cement Must Change — Now

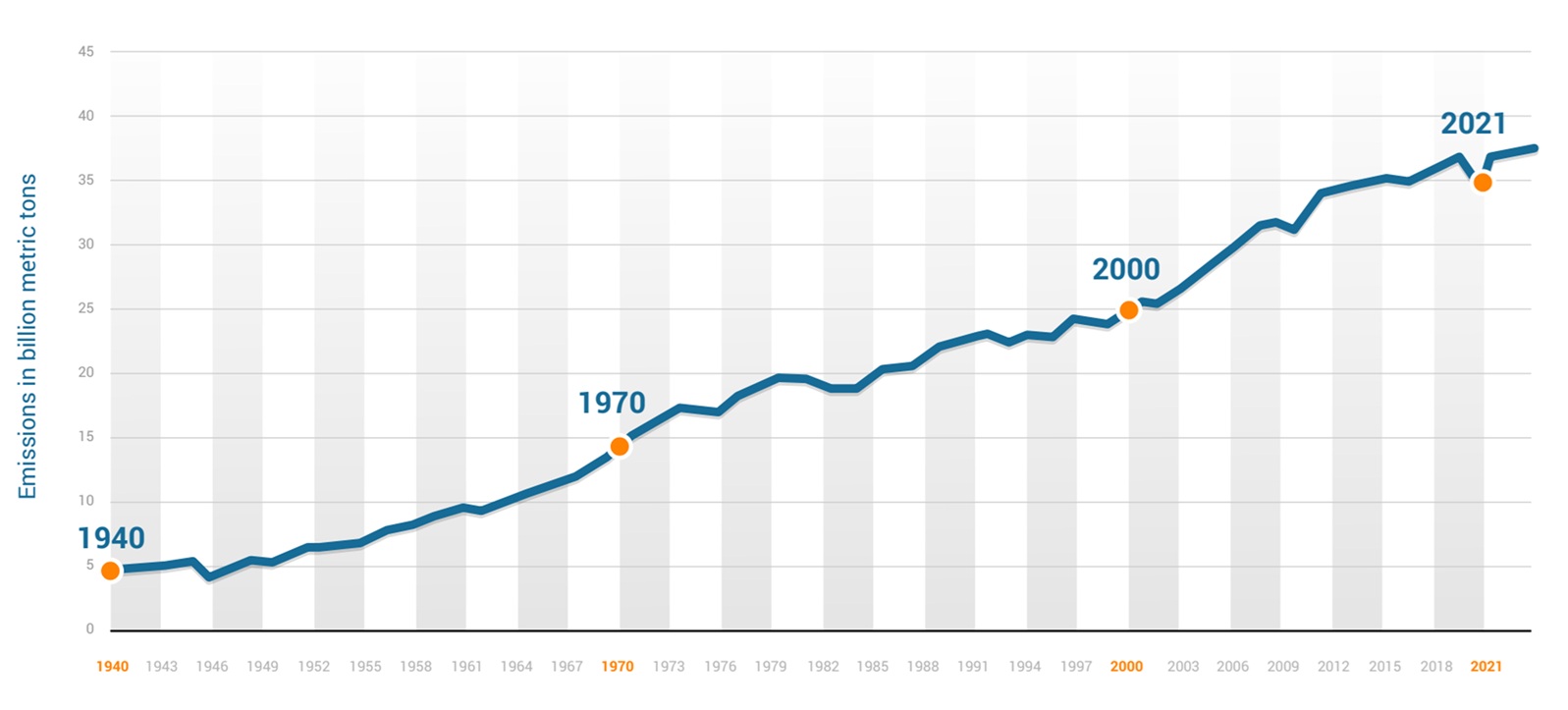

Global CO₂ Emissions Growth

In 2021, CO₂ emissions reached 38 billion tons, increasing to 38.5 billion in 2022

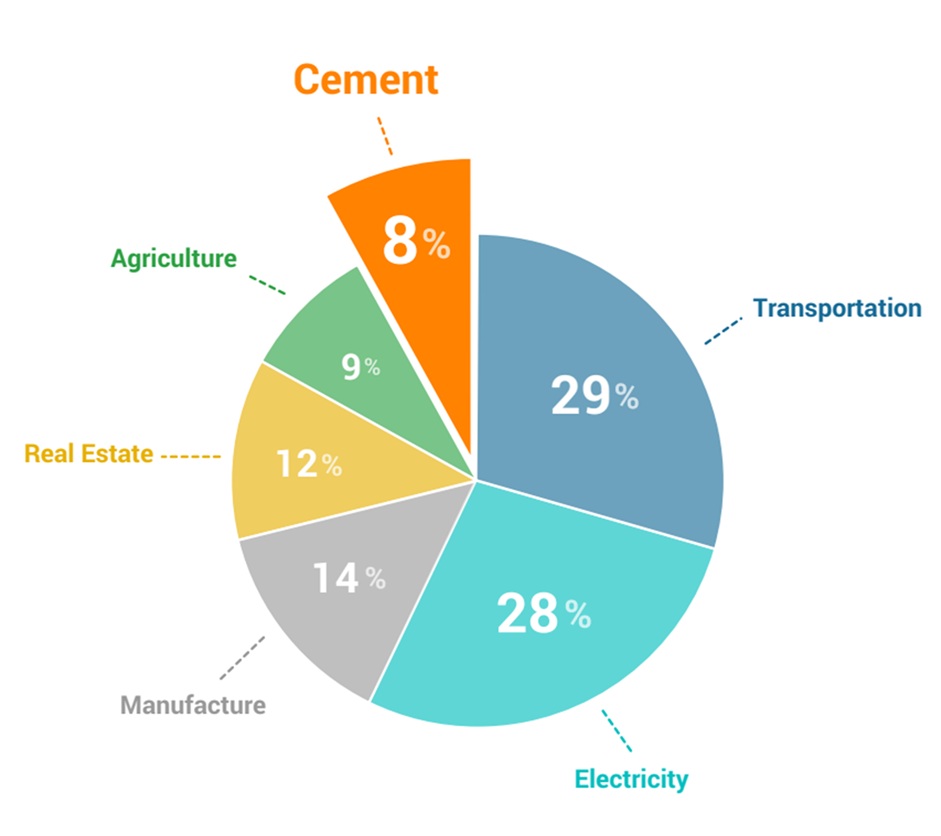

Cement's Global Impact

Cement production accounts for 8% of global CO₂ emissions

Problem

CO₂ emissions grow rapidly. Cement alone accounts for 8% of all global emissions.

Producing 1 m³ of concrete emits 150–250 kg of CO₂.

Motivation

Reduce cement usage without compromising strength.

Target

Enable stronger concrete with less cement using graphene nanomaterials.

Annual CO₂ emissions from cement production

Potential reduction in cement usage with graphene technology

Target year for carbon-neutral concrete industry

Our Technology and Solution

Our proprietary process transforms raw graphite into high-quality graphene for seamless integration into concrete production. This revolutionary approach enhances concrete performance while maintaining compatibility with existing manufacturing processes.

Unique Properties of Graphene

Graphene is a revolutionary nanomaterial with extraordinary properties that transform concrete at the molecular level, creating a superior building material for the future.

Strength

200 times stronger than steel, the strongest material ever tested

Electrical Conductivity

Exceptional electron mobility, superior to copper and silicon

Thermal Conductivity

Conducts heat better than all known materials at room temperature

Chemical Inertness

Highly resistant to chemical degradation and corrosion

Hydrophobicity

Natural water-repellent properties that reduce moisture penetration

Transparency

Nearly transparent despite its density, allowing for novel applications

Our Production Process

We've developed a scalable, efficient process to produce high-quality graphene and integrate it into concrete manufacturing.

Graphite Input

Raw graphite feedstock (natural or synthetic)

Processing Unit

Transforms graphite into liquid-phase graphene

Graphene Dispersion

High-concentration stable aqueous output

Concrete Integration

Inline dosing into mixing systems

Graphite Input

Raw graphite feedstock (natural or synthetic)

Processing Unit

Transforms graphite into liquid-phase graphene

Graphene Dispersion

High-concentration stable aqueous output

Concrete Integration

Inline dosing into mixing systems

Proprietary Technology

Our patented process creates high-quality graphene at industrial scale, with consistent quality and concentration. Unlike traditional methods, our approach is environmentally friendly and cost-effective.

- •Energy-efficient production process

- •Consistent particle size distribution

- •Scalable from laboratory to industrial volumes

Integration Benefits

Our solution seamlessly integrates with existing concrete production facilities, requiring minimal modifications to current processes while delivering transformative performance improvements.

- •Compatible with standard batching equipment

- •No special handling or storage requirements

- •Precise dosing systems for optimal performance

Technical Process

Step from theory into reality as we explore the scientific foundations behind our revolutionary graphene-concrete technology

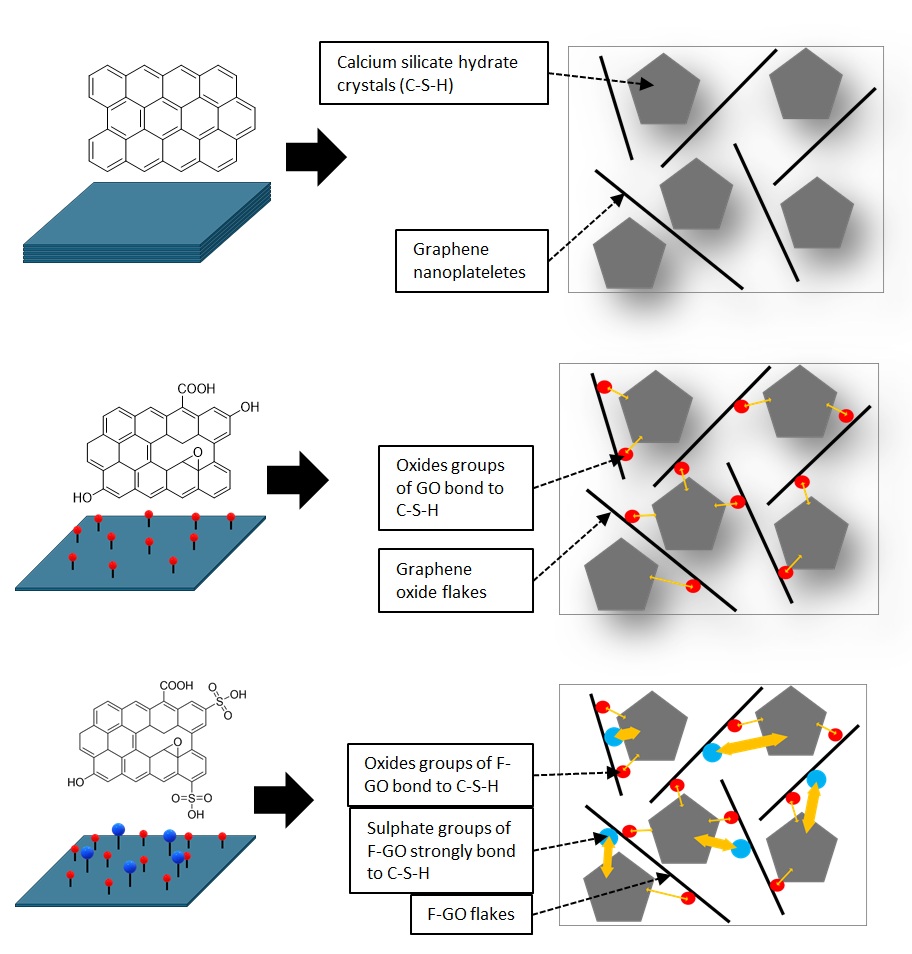

Molecular-level enhancement of concrete

Graphene-enhanced concrete leverages different forms of graphene for improved performance:

GNP (Graphene Nanoplatelets)

Provide physical reinforcement by filling pores and blocking microcracks.

GO (Graphene Oxide)

Enable both physical and chemical bonding with hydration products (C-S-H).

F-GO (Functionalized GO)

Feature sulfate groups for stronger interaction and enhanced bonding with the cement matrix.

Advanced Geometric Forms in Architecture

One of the most innovative directions in future architecture is the use of advanced geometric forms that make structures both lighter and stronger. A striking example is the Schwarz Primitive Surface — a type of minimal surface characterized by smooth curves and an intricate, porous lattice. Visually complex yet structurally efficient, it offers exceptional stability.

This geometry naturally occurs in structures like bones and coral, where strength must be balanced with minimal weight. When 3D-printed in concrete, Schwarz surfaces distribute loads evenly, allowing for significant material savings without compromising strength.

When combined with graphene-enhanced concrete, the impact is even greater. Graphene adds extraordinary strength; the geometry maximizes efficiency. Together, they create high-performance, lightweight structures using a fraction of the resources.

Biomimetic Design

This approach opens new possibilities for sustainable design — ideal for architects seeking to unite form, beauty, and resilience.

Schwarz Primitive Surface

A mathematical minimal surface that creates optimal strength-to-weight ratio in architectural structures.

Applications

Bridges & Tunnels

Extended lifespan with reduced maintenance for critical transportation infrastructure.

High-Rise Buildings

Superior strength-to-weight ratio enabling innovative architectural designs.

Industrial Facilities

Enhanced resistance to chemical exposure and heavy machinery vibration.

Marine Structures

Exceptional durability in saltwater environments with reduced corrosion.

Aerospace

Ultra-high-performance applications requiring precision engineering.

Highways & Runways

Reduced cracking and rutting under heavy traffic and extreme weather conditions.

Data Centers

Precise thermal management and vibration control for sensitive equipment.

Green Infrastructure

Reduced carbon footprint for environmentally conscious construction projects.

Key Benefits

Sustainability

- ✓Reduces CO₂ Emissions

Lower cement demand directly cuts the carbon footprint of construction.

- ✓Requires up to 30% Less Cement

Higher material performance allows for optimized formulations with reduced binder content.

- ✓Produced Without Chemical Emissions

Our graphene nanoplatelets are manufactured via clean physical processes — no harsh chemicals, no toxic byproducts.

- ✓Extends Infrastructure Lifespan

Improved durability and microcrack resistance result in fewer repairs and longer service life.

Cost Efficiency

- ✓Up to 30% Cement Savings

Optimized formulations reduce binder demand without compromising strength.

- ✓20–25% Lower Cost per m³

Less cement and improved performance translate to tangible savings per project.

- ✓Uses Low-Cost Graphite Input

No need for expensive precursors — our system works with affordable raw materials.

- ✓Payback Period Under 5 Years

Equipment investment is offset quickly through reduced material and transport costs.

- ✓Drop-In Compatibility

Seamlessly integrates into existing batching and mixing workflows.

About Us

Founded by a team of materials scientists and engineers, ConcreteGraphene is dedicated to revolutionizing construction through the application of advanced nanomaterials and sustainable practices.

Our Mission

We are developing next-generation construction materials by combining deep scientific expertise in graphene and concrete technologies.

Our goal is to enable stronger, longer-lasting, and more sustainable infrastructure — grounded in years of research, lab validation, and material innovation.

Future Development

2004–2022: Scientific Foundation

Decades of global research into graphene materials and cement chemistry laid the groundwork for scalable applications. Our team brings direct experience from leading labs and universities working at the frontier of this science.

2023–2024: Core Technology Development

We designed and validated a base formulation that integrates graphene into concrete, improving strength and durability across multiple mix designs.

2025–2026: Pilot Projects and Optimization

Field trials and collaboration with early adopters will refine our process, adapt it to various cement types and mixing conditions, and verify cost-performance benefits at scale.

2027–2028: Scaling and Harsh Environment Deployment

Rollout of specialized variants for high-load, coastal, and thermally extreme environments. Focus on industrial integration and manufacturing repeatability.

2029–2030: Sustainable Expansion

Wider international adoption and integration into green infrastructure initiatives, with ongoing improvement of life-cycle impact and supply chain footprint.

Leadership Team

Our world-class team brings together experts in materials science, engineering, and sustainable construction to drive innovation in the concrete industry.

Ready to Transform Infrastructure?

Connect with our engineering team to discuss how graphene-reinforced concrete can revolutionize your next project.

Contact Us Directly

We're ready to discuss your specific needs and how our technology can benefit your projects.

info@concretegraphene.com